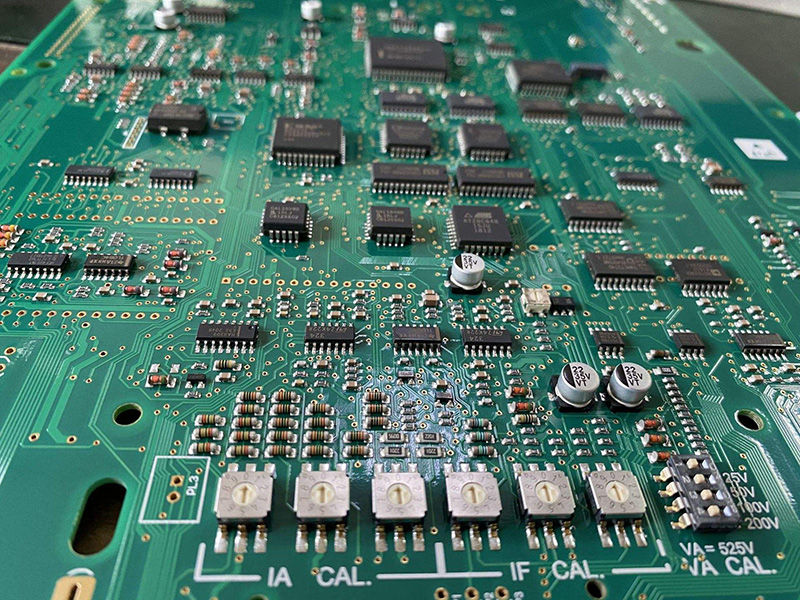

In most electronics, the surface-mounted and socketed components are physically supported and wired using a printed circuit board (PCB). A PCB is manufactured using a photolithographic method for applications that require delicate conductive traces, such as computers. However, printed circuit boards with sophisticated hardware, such as motherboards and graphics cards, can contain up to twelve layers. So, depending on the production scale, many PCB assembly processes exist. Simple bulk PCB manufacturing is what high-volume PCB assembly is. This kind of PCB assembly produces over 1000 PCBs. This method is typically used for conventional or custom PCB assemblies in great demand.

What is High-Volume PCB Assembly?

Printed circuit board (PCB) assembly made in high volume (i.e., more than 1000 assemblies in a single batch or 100,000) is called high-volume PCB assembly. The well-known electrical product manufacturers whose PCB assemblies are in high demand on the market handle this operation. Automating the high-volume PCB assembly process helps to make it effective and environmentally sustainable.

Application of High-Volume PCB Assembly

Large-scale and high-volume production of various appliances is possible with high-volume PCB assembly. The industries that can use high-volume PCB assembly are listed below.

- Automobile industry,

- Aerospace industry,

- Defense industry

- The communication sector will aid in creating communication

Steps involved in manufacturing of High-Volume PCB Assembly

Hillaman Curtis told us about the manufacturing steps of High-Volume PCB Assembly are as follows,

- Planning Phase

The materials required for the PCB assembly procedure must be ready. Components for solder masking, materials, PCB stack up, and production equipment are needed. Reflow ovens, positioning devices, and stencil printers are additional equipment required in this situation. With all of these at your disposal, you may consult the design and ensure everything is in its proper location. Check the material bill to make sure all the required components are there. After placing the supplies, you will arrange them before turning on your equipment.

- Printing using solder paste

Solder paste printing on the stackup will start the PCB assembly process for high-volume production. Squeegees and stencils are being used for solder printing. Another option is to print with jet solder paste.

- The component’s placement

During this phase, the PCB stackup and solder paste moved to the following machine. Facilitates selecting and arranging PCB components. Since a computer typically oversees everything related to the design, this process likewise proceeds at a breakneck pace. When everything is finished, you will examine the parts. We use Automatic Optical Inspection in this case. This checks for PCB-related issues.

- Soldering by Reflow

The PCBs then go to the reflow soldering machine. Here, all of the electrical connections are made. The ideal method of reflow soldering involves heating the PCB. The proper temperatures need to be used to connect wires. We can run an automatic inspection to locate or detect faults when the operation is finished. Also, keep in mind that the entire process happens quite quickly, manufacturing printed circuit boards in huge quantities.

Advantages of using High-Volume PCB Assembly

Accelerated assemblies told us about some benefits of using High-Volume PCB Assembly as follows,

- One-time design and prototyping procedure

Since PCB assembly is made in bulk, it is uniform. As a result, PCB design and prototyping are completed just once for all PCBs. The designers in this procedure must pay close attention to the design process. A single design error can result in a loss because it will affect over 1000 PCBs and more. Therefore, in this procedure, design and prototyping are carried out to guarantee the PCB’s efficient operation. Finally, the finished prototype is built and tested to ensure performance. Typically, in this process, look-alike-work-alike PCBs are favored.

- Production Uniformity

Due to established specifications, production is uniform. All of the PCBs will be created uniformly from the very first one to the very last one. As a result, this kind of PCB assembly can preserve feature consistency.

- Cost-Efficiency

This procedure is unquestionably economical. The parts and materials are bought in bulk, which lowers the price. In addition, bulk manufacturing reduces the cost of individual design, manufacture, and testing.

Conclusion

We occasionally need to upgrade our production process. And the current trend is toward automation. So if we adopt, our strategies will be updated, and we’ll eventually be forced to leave this business. Therefore, to achieve the greatest results, follow the customer’s specifications and adopt a high-volume PCB assembly procedure. If you are suspicious about whom to consider for it, Eashub PCB can be your best partner. However, do background checks on the company when choosing a partner for high-volume PCB fabrication to ensure qualitative results.